- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- HyAxiom

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

Doosan Heavy Industries & Construction installs 17,000-ton forging press

2017-04-23

- Company steps up efforts to develop supersized forged products by installing world’s largest forging press

- Forging plant expanded by 34% leading to greater production capacity

- Forging plant expanded by 34% leading to greater production capacity

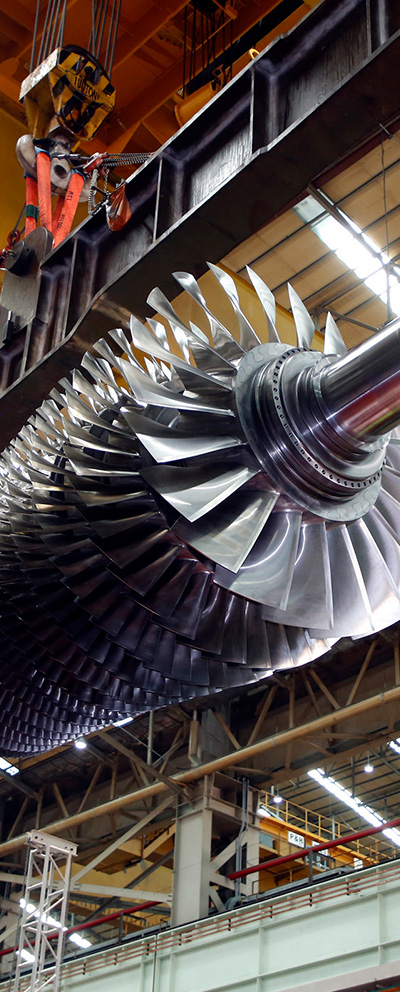

Doosan Heavy Industries & Construction held a ceremony to celebrate the installation of a new 17,000-ton forging press – the world’s largest to date – at the forging plant of its manufacturing complex in Changwon, South Gyeongsang province in South Korea. The forging plant is where steel ingot made up of molten metal gets heated up to be forged into certain shapes with a large-scale press.

The new 17,000-ton forging press is 29 meters tall and 9 meters wide, and it can forge steel ingot with the strength equivalent to 240,000 men pressing on the metal at the same time.

It is currently the world’s biggest four-pillar type forging press to date.

Doosan Heavy Industries had been working on the development of the 17,000-ton forging press since 2014, applying its own proprietary technologies and experience acquired from years of making cast & forged materials for large-scale power projects. Commercial operation of the press was initiated last April 3rd.

Doosan also expanded the size of its forging plant by nearly 34% to 73,748 m² for the new large-scale machine, replacing the existing 13,000-ton forging press that was operated for the past 35 years.

The company’s forging plant – which has been providing reliable materials for power generation and industrial facilities across the world – is now capable of producing 80,000 tons of forged materials a year with the new forging press, a weight that can be compared to 50,000 units of mid-sized sedans.

Casting & Forging BG CEO Jeog Jeon at Doosan Heavy Industries & Construction said, “Equipped with the 17,000-ton forging press, Doosan has gained a competitive edge over the major players overseas, including Japan, Italy and China in producing material, especially for large power generation equipment. Going forward, we plan to expedite our efforts to develop and deliver supersized forged products for power generation and industrial facilities, such as the next-generation advanced nuclear power reactors.”

Doosan Heavy Industries & Construction has a total of three forging presses - 17,000 ton, 4,200 ton, and 1,600 ton – enabling the company to produce a total of 140,000 tons of forged steel products annually.