- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- Business expanding at rapid pace in line with growing partnerships, following on heels of agreements with KAI and ADD

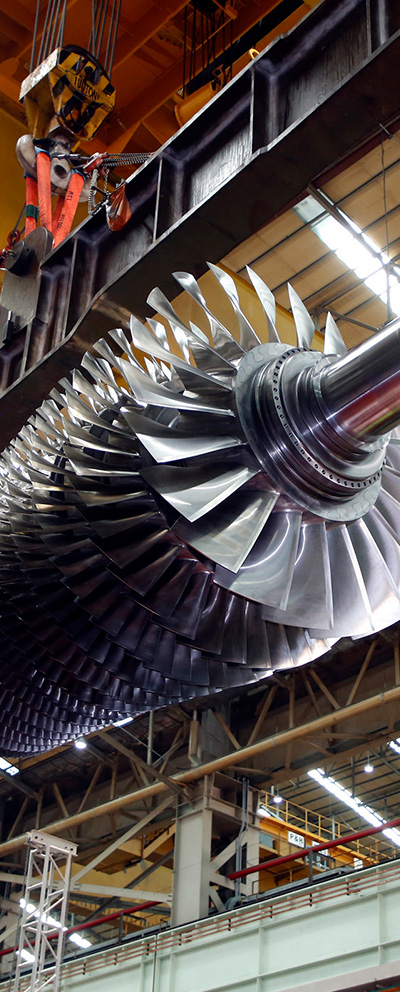

Doosan Enerbility announced on April 16th that it had signed a memorandum of understanding with Korean Air to cooperate on the development of aircraft engines and unmanned aerial vehicle(UAV) projects. With the MOU following on the heels of the agreement signed with Korea Aerospace Industries (KAI) last year, Doosan has now become partners with Korea’s two domestic aircraft system* manufacturers.

*Aircraft System: refers to an aircraft’s overall system consisting of various components and interacting sub-systems that enable the aircraft to operate efficiently.

The signing ceremony held that day at Doosan Enerbility’s headquarters in Changwon was attended by key figures from both parties, including Minseok Ko, Head of Gas Turbine Development at Doosan Enerbility, and Kyungnam Kim, Head of Korean Air Tech Center.

Under the terms of the MOU, Doosan Enerbility will be taking on the development of aircraft engines, while Korean Air will be focusing on the development of aircraft systems. The two parties will be collaborating on the development of mid to large-sized UAV engines with a thrust range of 5000-15,000lbf* and small-sized UAV engines with a thrust range of 100-1000lbf.

* 15,000lbf (thrust of 15,000 pounds-force, with ‘lbf’ used as the unit of force)

Doosan Enerbility has recently been increasing its scope of cooperation for aircraft engine development with parties in both the private and public sectors. In December of last year, Doosan had signed an MOU with Korea Aerospace Industries(KAI) agreeing to collaborate on the development of aircraft engines. This was followed by the signing of a contract for aircraft engine testing with the Agency for Defense Development (ADD) in January of this year. Such agreements are in alignment with the mid-to-long term aircraft engine development roadmap released by the South Korean government. According to this plan which aims at achieving localization of aircraft engine manufacturing, the government will be seeking to obtain technologies for 10,000lbf-class UAV engines and 15,000lbf-class aircraft engines by early 2030.

“To achieve the goal of localized manufacturing for a wide product lineup extending from small to mid-to-large sized aircraft engines, we are focused on engaging in related cooperation and development efforts,” said Seungwoo Sohn, CEO of Doosan Enerbility’s Power Services Business Group. “We will draw on our technological expertise and know-how accumulated from years of developing gas turbines for power plants to actively embark on development of aircraft engine technology and business expansion.”

Aircraft engines are key components that ultimately determine the performance of the aircraft. At present, only a handful of countries, such as the United States, United Kingdom, France and Russia, hold proprietary technology for developing such aircraft engines. Doosan Enerbility is a holder of proprietary technology for power plant gas turbines, which are structurally quite similar to aircraft engines. The company holds particular expertise in the development of hot parts, which are considered essential in aircraft engine development.

▲ On Apr. 16, Minseok Ko, Head of Gas Turbine Development at Doosan Enerbility (on the right), and Kyungnam Kim, Head of Korean Air Tech Center, sign the MOU on aircraft engine and UAV development at the signing ceremony held at Doosan Enerbility’s Changwon headquarters.

▲ On Apr. 16, Minseok Ko, Head of Gas Turbine Development at Doosan Enerbility (5th from the right), and Kyungnam Kim, Head of Korean Air Tech Center (4th from the left), pose for a group photo at the aircraft engine and UAV development MOU signing ceremony held at Doosan Enerbility’s Changwon headquarters.