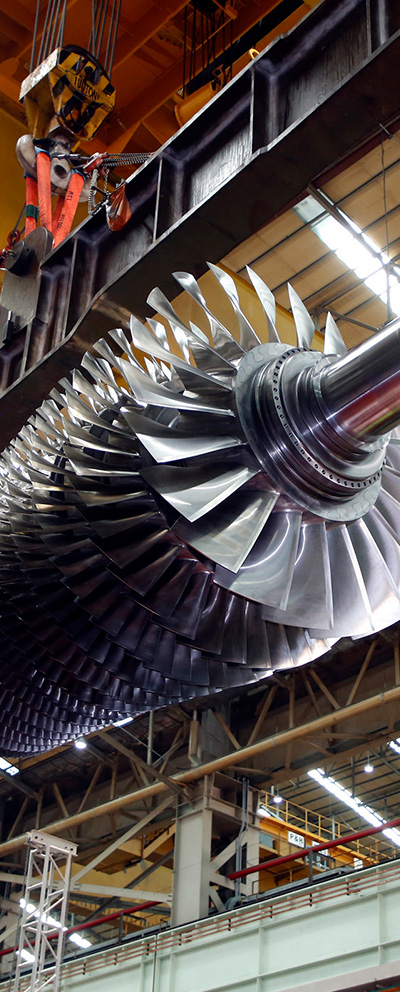

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- HyAxiom

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- Aiming to enhance performance of semiconductor machinery and “identify new application areas for AM parts”

On March 30th, Doosan Enerbility announced that it had signed a memorandum of understanding with the semiconductor machinery company Wonik IPS regarding metal additive manufacturing (AM)-related technology exchanges and joint research.

* Metal Additive Manufacturing(AM): Refers to the technology also known as “3D printing” which involves creating metal parts by building up layers of metal powder one layer at a time.

The signing ceremony which was held on March 28th at the Bundang Doosan Tower in Seongnam-si, Gyeonggi Province, was attended by the related parties, including Huibom Lee, Head of Strategy & Innovation Operation at Doosan Enerbility, and Myung-beom Lee, Head of Advanced Development at Wonik IPS.

With the signing of this MOU, the two parties agreed to conduct performance evaluations on additive manufactured parts applicable to next-generation chemical vapor deposition(CVD) systems, and to design and create prototypes for verification purposes. Furthermore, the two parties aim to continuously collaborate on satisfying the requirements of the semiconductor market, such as amending quality-related documentation to meet the quality control criteria for metal AM.

The AM sector in the global semiconductor market is constantly growing. According to Additive Manufacturing Research, a provider of industry analysis and market research reports for the AM sector, the global semiconductor additive manufacturing sector is projected to grow on average by 26% yearly from approximately KRW 230 billion in 2024 to KRW 2 trillion by 2032.

“This MOU was signed for the purpose of developing technology aimed at enhancing the performance of semiconductor machinery,” said Yongjin Song, Chief Strategy Officer of Doosan Enerbility. “With the application areas of AM technology expanding beyond the existing gas turbine and defense sectors to the semiconductor sector, we aim to actively develop new markets.”

Myung-beom Lee from Wonik IPS remarked, “Our two companies plan to actively engage in cooperation efforts to achieve the goals of metal AM technology exchanges and joint research.” He added, “By leveraging the technological know-how and experience we acquired over the years in each sector, we will lead the way to future technological innovation and endeavor to create new value.”

Since first applying the AM technology to power plant gas turbines in 2014, Doosan Enerbility has been steadily expanding its areas of business and partnerships. Last year, Doosan had signed a MOU with Pelagus 3D, a Singapore-based on-demand digital manufacturing platform operator for maritime and offshore spart parts, and another MOU in 2022 on technology development and marketing collaboration with EOS, the Germany-based global leader of 3D printing.

▲ On Mar. 28, Huibom Lee, Head of Strategy & Innovation Operation at Doosan Enerbility (on the left), and Myung-beom Lee, Head of Advanced Development at IPS, sign the MOU at the “AM Technology Exchanges & Joint Research MOU Signing Ceremony” held at Bundang Doosan Tower.

▲ On Mar. 28, Huibom Lee, Head of Strategy & Innovation Operation at Doosan Enerbility (4th from the left), and Myung-beom Lee, Head of Advanced Development at IPS (3rd from the right), pose for a group photo with the related parties at the “AM Technology Exchanges & Joint Research MOU Signing Ceremony” held at Bundang Doosan Tower.