- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

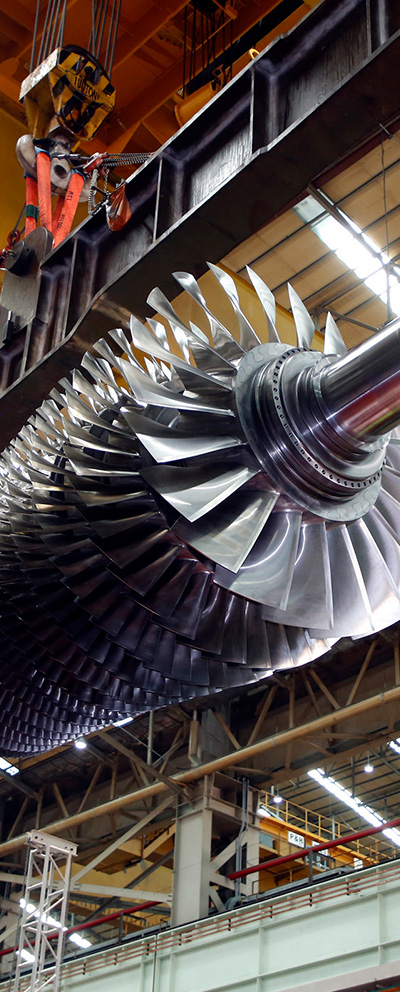

- Digital technology accumulated from power sector expected to lead to greater energy efficiency and enhanced quality of steelmaking facilities

Doosan Enerbility is rolling out its digital technology capabilities, which had been built up over the years in the domestic and international power markets, at a wider scale to also be applied to the steelmaking industry.

On July 8th, Doosan Enerbility announced that it had signed the “Data Analytics Service Agreement for AI Application in Sintering Process” with the Research Institute of Industrial Science and Technology (RIST), a research organization specializing in steelmaking and environmental energy technologies.

* A research institute established with 100% equity investment from POSCO, which plays a central role in driving the key business initiatives of the POSCO Group.

Under the terms of the agreement, over the months leading up to this coming December, Doosan Enerbility will be analyzing the AI applicability of the POSCO steel mills using sinter machine data. Sintering is a process where loose powder material is subjected to high temperature and pressure to form a solid mass of material. Before molten metal is produced at the steel mills, the irregularly shaped iron ore particles are evened out into substances of consistent size through the sintering process.

“With the signing of this agreement, we will be combining the strengths of Doosan Enerbility’s digital technologies, which have been verified at both domestic and overseas power plants, and RIST’s innovative research and development performance, which we expect will lead to improvements in the energy efficiency of sinter machines and higher quality of iron ore sinters,” said Yongjin Song, Chief Strategy Officer of Doosan Enerbility.

Since 2013, Doosan Enerbility has been running the “Digital Innovation” organization, which consists of the Data Analytics Team and Data Solutions Team. The company has supplied an AI-based optimization solution to a 1000MW power plant in Korea to be connected with the control network, thereby building customer trust and improving operational efficiency. Doosan has been expanding the reach of its digital solutions by offering a wide range of products that include “PreVision,” a prediction and diagnostics solution, and a non-destructive testing(NDT) solution.