- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

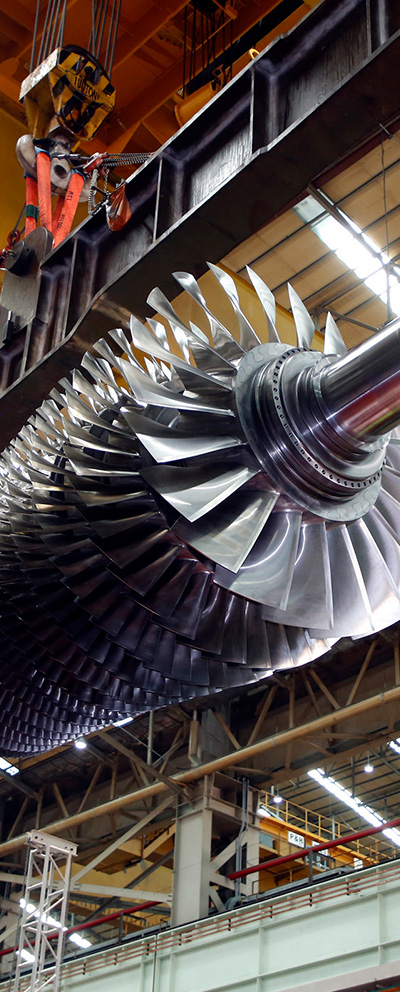

Doosan Enerbility announced on December 12th that it had obtained a type certification from DEWI-OCC, the Germany-based international certification authority, for its 8MW offshore wind power system (Model Name: DS205-8MW), making Doosan the first company in Korea to accomplish such a feat.

Since 2018, Doosan Enerbility has been pursuing “development of the 8MW large-capacity offshore wind power system,” with the support of the Korea Institute of Energy Technology Evaluation and Planning(KETEP) which is under the Ministry of Trade, Industry and Energy. This past January, a prototype was implemented in Yeonggwang of South Jeolla Province, after which a demonstration run was carried out, followed by the securing of the international certification. The international certification received by Doosan is only awarded to those who have satisfied all the applicable criteria in the areas of design evaluation, manufacturing evaluation and type testing.

The DS205-8MW, the offshore wind turbine model with the largest capacity to date in Korea, was designed to be suitable for the Southwest Sea environment, which has notably lower wind speeds compared to Europe, which is the leader of offshore wind power. The diameter* of the rotor was lengthened to 205 meters (blade length: 100m), so that the wind turbine could be used even when the average wind speed is 6.5m/s and thereby making it possible to record a utilization rate over 30%.

*The rotor diameter refers to the diameter of the circle drawn by the tip of the turbine blade. The longer the diameter, the larger the surface area of the blade for receiving the wind, leading to higher power generating efficiency. If the blade length is doubled, the surface area for receiving the wind would become four times larger.

The 100 meters-long blade was developed jointly by Doosan Enerbility with the Korea Institute of Materials Science (KIMS) and the blade manufacturer Human Composites. At the Buan Wind Power Testing Facility, an internationally certified testing institute, the structural soundness and security of the blade were verified by conducting repeated fatigue load tests on the design lifecycle of 25 years and load testing under extreme conditions such as typhoons.

“We are seeking to expand the market by introducing the 8MW offshore wind turbine, which was developed jointly by the local industry, academia and research sectors**, to the Korean offshore wind power market which has been the stage of competition for global wind power companies,” said Hongook Park, CEO of Doosan Enerbility’s Power Services Business Group. He added, “We aim to increase the local manufacturing of parts, which is currently over 70% to an ever higher rate, and to apply our local technology and manpower to the area of turbine maintenance services, which has largely been dependent on overseas companies until now. This will ultimately help to contribute to promoting the domestic offshore wind power ecosystem.”

** Doosan Enerbility supervised the design, manufacturing and demonstration process, Human Composites Co. handled the blade manufacturing, KIMS was in charge of the blade testing and certification, Seil Engineering Co. was responsible for substructure design, transportation and installation, while Seoul National University was in charge of the noise reduction for turbine blades.

Doosan Enerbility, which first commenced the wind power business in 2005, currently holds the 3.3MW, 5.5MW and 8MW wind turbine models. The company is working to expand the wind power business, as reflected in the company building its second wind turbine shop last year to enable manufacturing of the 5.5MW model, and seeing to the preparations for setting up the 8MW wind turbine shop, and restructuring the wind power organization to become larger and planning for development of next generation, ultra large models.

▲Views of Doosan Enerbility’s 8MW offshore wind turbine, which was installed this past January at the National Wind Power Demonstration Center in Baeksu-eup, Yeonggwang-gun of South Jeolla province.

▲Views of Doosan Enerbility’s 8MW offshore wind turbine, which was installed this past January at the National Wind Power Demonstration Center in Baeksu-eup, Yeonggwang-gun of South Jeolla province.