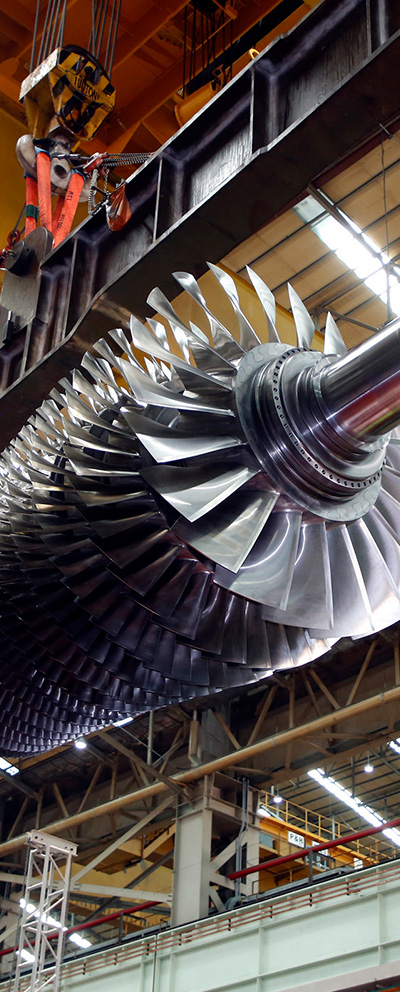

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- HyAxiom

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- Hydrogen production from waste plastic expected to contribute to resource circulation and carbon neutrality, and to be applied to fuel cells and hydrogen gas turbines

Doosan Heavy Industries & Construction has embarked on the development of technology for producing hydrogen using waste plastic and vinyl (hereinafter referred to as “waste plastic”). To this end, the company announced on May 6th that it had signed a business partnership MOU with RevoTech, a company that specializes in the continuous pyrolysis of waste plastic.

RevoTech will be applying its continuous pyrolysis* technology to convert waste plastic into gas, while Doosan will be developing the main equipment and processes for reforming the product gas into hydrogen. The continuous pyrolysis technology is achieved through the continuous input of raw materials which in turn enables continuous production, leading to greater ease in expanding the scale of processing and securing economic feasibility.

* Pyrolysis: Heating of an organic material that leads to the chemical compounds of the material to thermally decompose into two or more types of substances. The pyrolysis of waste plastic refers to the thermal degradation of plastic, which involves high molecular weight hydrocarbons being broken down into smaller molecules at high temperatures to produce valuable byproducts in the forms of gas or liquid.

Doosan is working on developing a hydrogen reformer that has the capacity to produce 0.3 tons of hydrogen per day by 2021 and plans to have this installed for operation at RevoTech, which is located in Mungyeong of North Gyeongsang Province. A demonstration will be carried out thereafter, before commercially launching the technology for producing more than 3 tons of hydrogen per day from waste plastic.

Doosan Heavy’s CSO Yongjin Song remarked, “We see more than eight million tons of waste plastic being generated in Korea every year, but we will now be able to apply this technology to the four million tons of waste plastic that usually go into landfills, incinerators or are used as solid refuse fuel(SRF).” He added, “The hydrogenation of waste plastic contributes to resource circulation and carbon neutrality, and the hydrogen produced can be used for fuel cells and hydrogen gas turbines, among other things.”

Doosan Heavy, which has been focused on building up its eco-friendly energy business, is widening its reach to include the hydrogen business. It is currently constructing Korea’s first hydrogen liquefaction plant within the complex of its Changwon plant, with plans to have it built by 2022. The production of green hydrogen based on water electrolysis using wind power is also well underway on Jeju island.

▲Waste Plastic Hydrogenation Process Flow

▲Doosan Heavy CSO Yongjin Song (on the left) and RevoTech CEO Byung-jik Hwang pose for a photo at the “MOU Signing Ceremony for Development of Waste Plastic Hydrogenation Technology” held at the Bundang Doosan Tower