- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- HyAxiom

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- Cask to be used for storing spent fuel at TMI Nuclear Power Plant Site in Pennsylvania

Doosan Heavy Industries & Construction became the first Korean company to export a cask for storing spent fuel.

Doosan Heavy Industries & Construction announced on March 25 that it had recently supplied five sets of a vertical concrete cask (VCC) to the TMI Nuclear Power Plant located on the Three Mile Island in Pennsylvania, U.S.

The cask is a special container used to transport and store spent fuel discharged after burned in nuclear reactors core. The container requires a special design and advanced manufacturing technology and know-how since it must safely manage the radiation and heat from spent fuel. The casks exported by Doosan are heavy-weight objects with a height of about 5.7 meters, diameter of 3.4 meters, and a weight of more than 100 tons.

Doosan Heavy Industries & Construction supplied five sets of cask according to terms of the supply contract that was signed with the U.S.-based NAC(Nuclear Assurance Corporation) at the end of 2019. An additional contract was signed to also deliver two sets of a transportable storage canister, a key component of the cask, in June.

“Our business partnership with NAC lays the foundation for us to enter the overseas cask market in full force and opens the door to new opportunities, so that we may significantly upgrade our manufacturing know-how of Korean-type casks. As we also expect to see continued demand in Korea, we plan to aggressively target both the domestic and overseas cask markets,” said Kiyong Na, Doosan Heavy’s Nuclear BG CEO.

Doosan is building a wide cask lineup suitable for the nuclear environment in Korea. After signing the “Agreement on Joint Development of Korean-Type Casks” with NAC in 2015, Doosan performed technology transfer leading to development in 2017 of the Doosan-DSS21, a Korean-type dry-storage cask that meets the stipulations of Korean Nuclear Safety Act and environmental conditions. Having secured in-house design capabilities, Doosan then developed the DSS24 and DSS32 models, upgraded models with larger storage capacity, and the DPC-24, a cask that can be used for both storage and transporting of spent fuel. In 2019, Doosan applied for a design license to the US NRC to verify the safety of its design, and it expects to receive the license in June.

Doosan has a supply chain established with numerous local suppliers in Korea for cask manufacturing, which will be used to supply safe and economically efficient casks to its customers.

Casks are classified into transport, storage, and dual transport/storage casks according to its use and metal or concrete casks depending on the container material. The main components include a basket for supporting dozens of nuclear fuel bundles, a canister to prevent the release of radioactive materials to the outside, a special shielding material to shield radiation, and an outer structure to ensure structural safety. Spent fuel is stored in a wet storage tank for at least five years to be cooled sufficiently after burned in a nuclear reactor core and transported to a cask for dry storage. It is finally stored in an underground facility.

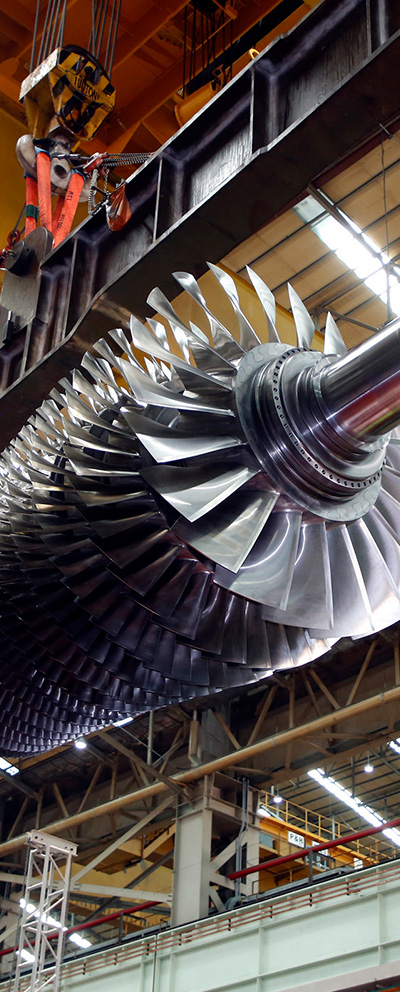

▲Manufacturing process of the cask for TMI Nuclear Power Plant in the U.S.

▲Manufacturing process of the cask for TMI Nuclear Power Plant in the U.S.

▲Cask in transport after arriving in the United States