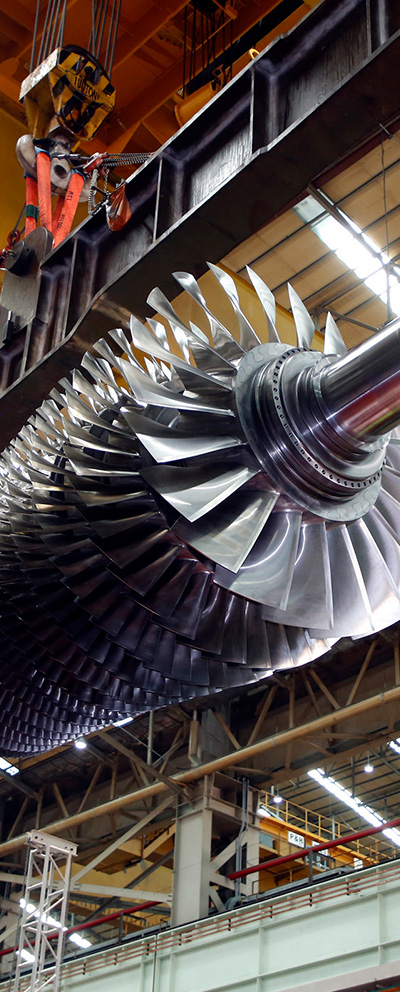

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- PCHE orders won for hydrogen charging stations, gas turbines and International Thermonuclear Experimental Reactor (ITER) ... Plans in place to expand into other areas such as fuel cells and LNG carriers

Doosan Heavy Industries & Construction is penetrating the market for printed circuit heat exchangers (PCHE), the so-called next-generation heat exchangers. The company announced on December 23 that it had secured the core technology for flow path design and the process technology and had recently installed a 600 ton hot press, which has the capacity to manufacture large PCHEs.

A heat exchanger is a device designed to exchange heat between two or more fluids (such as water, air, hydrogen, nitrogen) for the purpose of either cooling or heating the fluid. A PCHE is an upgraded heat exchanger that is built by having the photochemical machining process applied to create microchannel flow paths into a flat plate, with the plates then being stacked together and diffusion bonded.

A PCHE boasts of a minimum 90 percent improvement in heat exchanging efficiency compared to the conventional tube heat exchangers as it can be manufactured into a compact size that is one-tenth the size of conventional heat exchangers or even smaller. Moreover, it uses high-grade materials, such as stainless steel and superalloys, so that it can withstand even harsh operating conditions such as ultra-high temperatures reaching up to 900℃ and ultra-high pressure of up to 1500 bar. The demand for the compact-size PCHE is expanding in various fields owing to its advantage of enabling heat exchange in limited spaces.

Doosan was recognized for its superior technology when winning an order for a PCHE prototype to be installed at a domestic hydrogen charging station. The company is now preparing the supply for follow-up projects. Furthermore, the recent installation of the 600 ton hot press has led to the winning of new orders to manufacture a PCHE for gas turbines and a large-sized PCHE for ITER (International Thermonuclear Experimental Reactor).

“We were able to secure the flow path engineering technology by utilizing our R&D specialists, who possess heat exchanger engineering expertise for power generation, and also got an early hold on the capability for manufacturing PCHEs by leveraging our forging press operating experience. We plan to expand our business into other fields, such as hydrogen, LNG carriers, gas turbines and fuel cells,” said Kiyong Na, Head of Doosan Heavy’s Nuclear Business Group.

The PCHE market in Korea is forecasted to grow to a market size of around KRW 200 billion by 2030.