- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

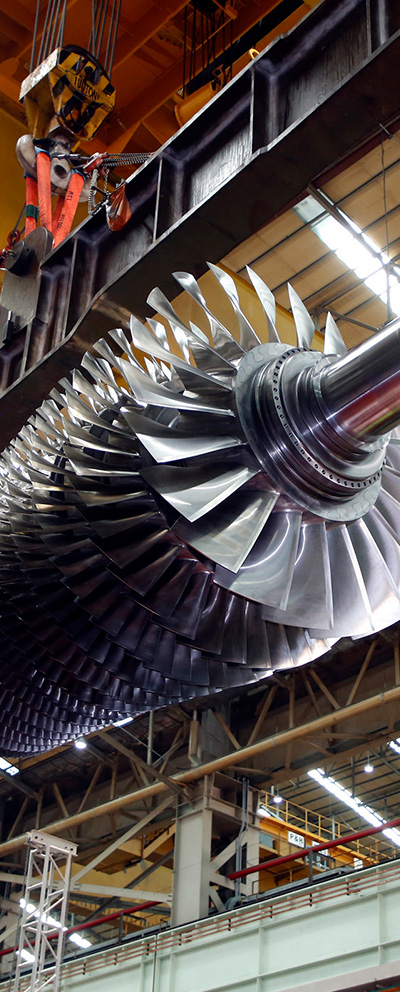

- Construction underway for 3D printing fabrication shop at Changwon headquarters…Sales of KRW 200 billion targeted for 2025

Doosan Heavy Industries & Construction announced on July 00 that it had obtained the AS9100 quality management certification for aerospace. The certification enables Doosan to now engage in business in the aerospace parts sector.

Being an international standard established by the International Aerospace Quality Group (IAQG), AS9100 reflects the safety, reliability and special conditions required in the global aerospace industry. It is an essential certification needed to enter the aerospace business. The scope of the certification obtained by Doosan covers 3D printing development and manufacturing for the aviation, space, and defense industries.

3D printing is the technology of manufacturing parts by using laser to melt metal or plastic powder deposited layer-by-layer. The advantage of this technology is that it can be used to create complex designs that would otherwise be difficult to implement with conventional processing technologies. This technology also helps to significantly reduce the manufacturing time and costs.

Doosan Heavy first adopted 3D printing technology in 2014 to promote a more advanced method of manufacturing power plant components, such as gas turbines. Since then, the company has invested about KRW 20 billion to build a fabrication shop exclusively for 3D printing at its Changwon headquarters and also installed a PBF*large metal 3D printer, one with the capacity to produce metal parts of the largest size in Korea.

* PBF (Powder Bed Fusion): As a metal 3D printing technique, PBF involves spreading out metal powders in a very thin horizontal layer and fusing them together layer-by-layer, by utilizing a high-powered industrial laser or electron beam.

“This certification is significant since it enables our company to widen the application of 3D printing technology from the production of power plant parts to also include aerospace parts. We intend to increase sales in the 3D printing materials business to KRW 200 billion or more by 2025,” said Yongjin Song, Doosan Heavy’s Chief Strategy Officer.

According to the 3D printing market analysis firm SmarTech Analysis, the size of the metal 3D printing market is forecast to grow dramatically from USD 590 million in 2018 to as much as USD 10 billion by2024.

▲AS9100 certificate issued to Doosan Heavy by IAQG