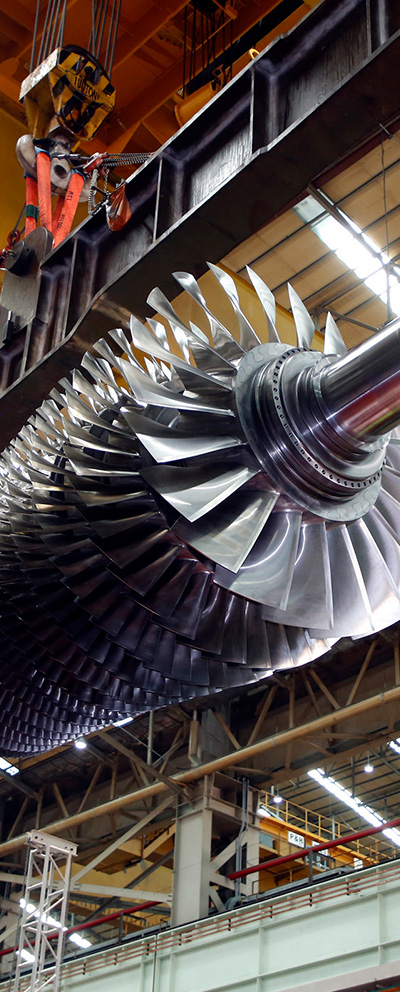

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- HyAxiom

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

Doosan Group Vice Chairman Geewon Park, Senior Management Team Attends CES 2019

2019-01-06

- Staying on top of the latest digital trends, seeking out new business opportunities

- Driving momentum for Digital Transformation at the corporate level

- Driving momentum for Digital Transformation at the corporate level

Doosan announced on Jan. 6 that Doosan Group Vice Chairman Geewon Park and a management team will attend the Consumer Electronics Show (CES) 2019, held in Las Vegas, Nevada.

Vice Chairman Park and the accompanying officials—including Hyunsoo Dong, vice chairman of Doosan Corporation’s Business Division; Wonjoon Hyoung, president and chief digital officer (CDO) of Doosan Group; and Scott Park, president and CEO of Doosan Bobcat—are looking to get an update on the latest trends and seek out new business opportunities during the visit. Vice Chairman Park plans to focus on examining the robotics, self-driving and Internet of Things (IoT) technologies exhibited by other global companies to find ways to integrate these trends into the Group’s existing businesses and develop new business ideas.

Doosan’s top executives have taken frequent tours to attend major industry events—e.g., the CES in the U.S. and Hannover Messe in Germany—to stay on top of the current technology trends. With its continued interest in developing new technologies and businesses, the Group has successfully identified its new growth engines such as collaborative robots and fuel cell packs for drones, and has fostered a culture of Digital Transformation.

Doosan’s collaborative robots went into mass production in 2017, and they garnered acclaim for the various solutions presented during Automatica 2018, Europe’s largest trade fair for smart automation and robotics held in Munich, Germany, in June. By focusing on the quality of its product offerings, Doosan has built 13 sales channels in eight countries, including Germany—a smart factory powerhouse—France and China, in just one year after the launch of mass production.

The company also revealed its unmanned aerial vehicle (UAV) fuel cell technology for the first time at InterDrone 2018 in September. The technology was developed in-house and is scheduled to go into mass production within this year. By offering about two hours of flight time on a single charge, it helps overcome the limits of drones powered by the previous battery technology, which were only able to fly for a little over 30 minutes. The technology is expected to be used for various applications, including power plant management, forest monitoring, construction and agriculture.

Doosan’s digital transformation efforts are opening up new horizons within the established business sector as well.

Doosan Heavy Industries & Construction has supplied an artificial intelligence (AI)-based digital solution to power plants in India that went into operation in November. With Doosan’s AI solution, power plant operators could improve the plants’ operating efficiency and reduce pollutant emissions such as nitrogen oxides (NOx) by analyzing hundreds of thousands of operating scenarios.

Meanwhile, Doosan Infracore has successfully demonstrated its 5G ultra-long-range remote control device for construction equipment. At Bauma China, one of the largest construction machine exhibitions in Asia, held in November, an unmanned excavator located in Incheon was remotely controlled from the exhibition venue, which was located about 880 kilometers away. The technology is expected to be widely used for tasks in hazardous or toxic environments that are considered too dangerous for humans.

Furthermore, Doosan offers its DoosanCONNECT™ telematics service that enables the remote monitoring of construction equipment using information communications technology (ICT), while striving to further advance its state-of-the-art technologies by forming partnerships with other autonomous driving and AI firms.