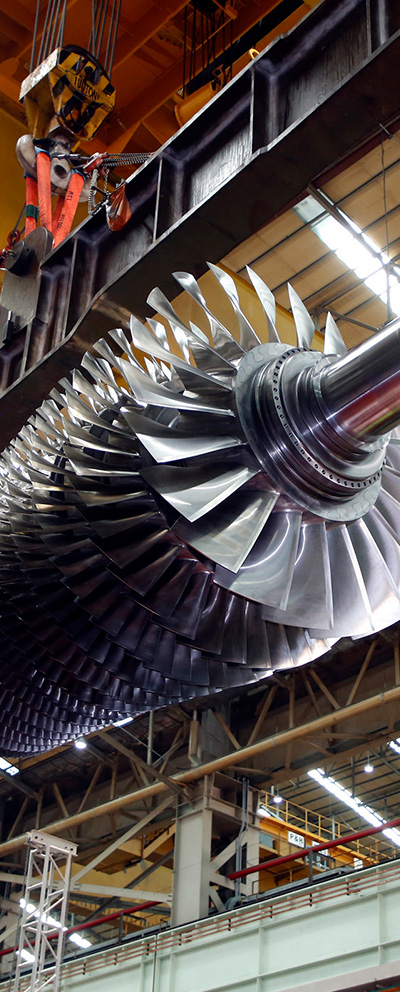

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

Mass Production of Doosan Robotics’ Four Collaborative Robot Models Begins

2017-12-20

- Manufacturing facility opens in Suwon Industrial Complex; annual production capacity of 20,000-plus units

- Its own collaborative robots integrated into main manufacturing process to make other robots

- Its own collaborative robots integrated into main manufacturing process to make other robots

On Dec. 20, Doosan Robotics (CEO Byungseo Lee) announced the grand opening of its collaborative robot manufacturing facility with an annual production capacity of 20,000-plus units. The new 4,451-square-meter factory was built in the Suwon Industrial Complex in Gosaek-dong, Suwon-si, Gyeonggi Province, and all four of its models went into mass production.

The new production facility is designed to produce high-quality collaborative robots, as it features a foolproof* system to prevent misuse problems by workers in advance, as well as an in-line process tester (IPT) that verifies the quality of assembly and parts in each step of the manufacturing process. Its collaborative robots are also integrated into the main manufacturing process, working side by side with humans to make other collaborative robots.

Doosan’s collaborative robots are equipped with an efficient collision detection sensor that guarantees the safety of nearby humans. With a repeatability of ± 0.1 millimeter and high-performance torque sensors*, the machines are capable of carrying out more sensitive processes that previously required the dexterity of human hands while enhancing safety. Depending on the model, the robots can carry up to 15 kilograms, and the robotic arms’ maximum work envelope is 1.7 meters.

Iljin Group, the first customer of Doosan Robotics, plans to integrate collaborative robots into the manufacturing process of its major affiliates by 2018, and use them more extensively throughout the group afterward. Hyundai Motor Company has been involved in the product development process since 2015 and is now looking to adopt Doosan’s collaborative robots on its factory floor. Furthermore, companies in a wide range of sectors, including electronics, cosmetics, foods and furniture, are carrying out field tests to adopt collaborative robots.

Upon the launch of mass production, Doosan Robotics is now focusing on building domestic distribution channels. Starting from next year, the company looks to expand to overseas markets with an annual sales goal of 1,000-plus units by next year and 9,000-plus units by 2022.

“The grand opening of the Suwon production facility and the launch of mass production mark the company’s first step taken in the collaborative robot market, which is expected to grow rapidly on the back of the advent of the fourth industrial revolution,” said a Doosan Robotics official. “Through our continuous R&D efforts and investments, we strive to establish a leading position as a front-runner and lead market growth.”

* Foolproof: A control system or control unit design which prevents errors and misuse problems by human users.

* In-line process tester (IPT): A procedure for verifying the quality of the assembly and parts in each product manufacturing step.

* Torque sensor: A sensor that measures rotational force. Doosan Group Chairman Jeongwon Park (third from left) and Doosan Group Vice Chairman Geewon Park (second from left) examine the manufacturing process of collaborative robots during his visit to Doosan Robotics’ Suwon factory on Dec. 19.

Doosan Group Chairman Jeongwon Park (third from left) and Doosan Group Vice Chairman Geewon Park (second from left) examine the manufacturing process of collaborative robots during his visit to Doosan Robotics’ Suwon factory on Dec. 19.