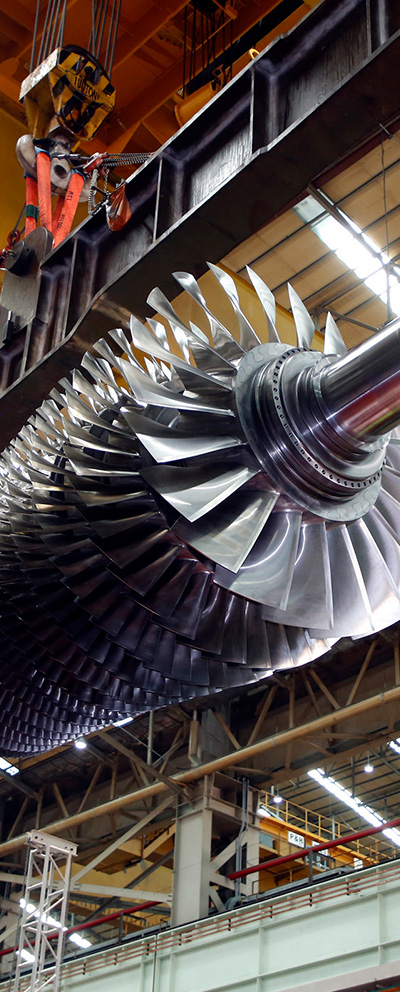

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- Solidifying position as global SMR foundry, with increased cooperation expected with NuScale on future follow-up projects

▲Aerial view of NuScale Power SMR plant (provided by NuScale Power)

Doosan Enerbility, which is aiming to position itself as global SMR foundry, has commenced production of the key materials that are essential for the construction of small modular reactors (SMRs).

Doosan Enerbility announced on March 10th that it had signed a contract with NuScale Power to manufacture the materials to be used in the production of SMRs. The materials are to be applied to the NuScale SMR plant that is being built for the Utah Associated Municipal Power Systems* Carbon Free Power Project (CFPP), the first SMR project to be pursued in the States. The SMR plant, which is situated in the state of Idaho and scheduled to be built by 2029, will have six 77MW NuScale power modules deployed to collectively generate 462MW of electricity.

* Utah Associated Municipal Power Systems (UAMPS): Electric energy provider in Utah, USA.

Since 2019, Doosan Enerbility has been working with NuScale on the SMR manufacturability review and prototype development. In April last year, the two companies signed an agreement to commence full-scale SMR manufacturing, with Doosan also completing production of the forged materials used in the SMRs. Under the recently signed agreement, Doosan will be manufacturing the key materials, such as the large forged materials, steam generator tubes and welded parts, required for the six modules that are to be deployed at the UAMPS CFPP plant. Manufacturing of the reactor is scheduled to start at the end of this year. Doosan Enerbility and NuScale Power are also collaborating on the additional manufacturing of key materials that are to be used in the follow-up project that is slated to be completed by 2029.

“The U.S. Nuclear Regulatory Commission (NRC) recently issued a final rule to certify NuScale’s innovative SMR design, which gives testament to NuScale’s status as the leading technology in the global SMR market,” said Jongdoo Kim, CEO of Doosan Enerbility’s Nuclear Business Group. “Doosan is proud to take part in the construction of a NuScale SMR, offering clean and carbon-free energy projects to tackle climate change.”

“Finalizing and submitting this order to our valued partner, Doosan, showcases NuScale’s transition to the manufacturing phase of our modules and highlights our advanced position in the market to deploy our SMR technology to customers by the end of the decade,” said John Hopkins, President and CEO of NuScale. “Our strong relationships with experienced partners like Doosan demonstrate NuScale’s robust global supply chain and positions us to meet the growing interest for NuScale VOYGR power plants that we are seeing around the world.”

In 2020, NuScale Power’s SMR became the first SMR design to be certified by the U.S. NRC. The NuScale Power Module is the first-ever SMR model to receive the NRC standard design certification. NuScale is engaged in not only the successful delivery of the UAMPS CFPP project, but is also expanding its SMR business reach at a global scale to markets such as Europe and the Americas.