- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

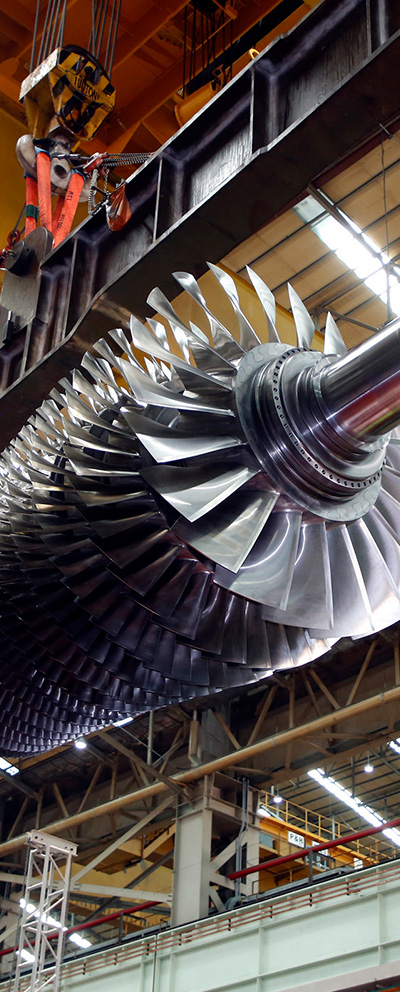

- Application of 3D printing technology widened to cover not only power plant gas turbines but also aircraft components

Doosan Heavy Industries & Construction announced on April 13 that it had supplied parts made using 3D printing technology for Korea’s first indigenous fighter aircraft, the KF-21 jet.

The parts supplied are components that form part of the fighter jet’s air circulation system. Doosan will be supplying parts for a total of six fighter jet prototypes, Prototypes No.1 to 6, the first one of which was released at the recent KF-21 rollout ceremony.

Ever since Doosan signed the “MoU for Cooperation on Aircraft Forgings and Localized 3D Printing-Based Manufacturing” with Korea Aerospace Industries (KAI) in 2019, the company has been working on applying 3D printing technology to parts manufacturing for the KF-21 fighter jet. As part of the efforts to promote more localized manufacturing of components, the two parties plan to actively apply 3D printing technology in the mass production of products as well.

“We had already been applying 3D printing technology in the manufacturing of gas turbine parts for power plants, but this recent accomplishment is significant as we have now widened the scope of application to include parts manufacturing for the aerospace and defense industries as well,” said Yongjin Song, CSO of Doosan Heavy Industries & Construction.

The 3D printing technology applied in the parts manufacturing process is a technique that uses a laser beam to melt and fuse together metal or plastic powder layer by layer to form a three-dimensional object. The benefits of the technology lie in that it helps save on manufacturing costs and dramatically reduces the time required for manufacturing. For example, if a metal 3D printer is used to produce the parts for a gas turbine combustor, the nitrogen oxide emissions would drop by more than 40 percent and the delivery time would be shortened by more than 20% compared to the conventional machining process.

According to SmarTech Analysis, the leading provider of market research and industry analysis in the 3D printing sector, the metal 3D printing market is forecast to rapidly grow to a projected market size of 10 billion dollars by 2024.