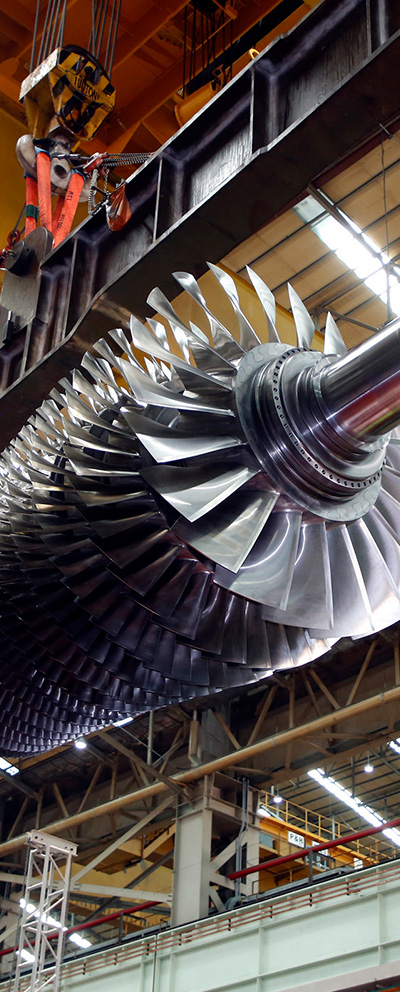

- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials

- Doosan Digital Innovation

- Doosan Corporation Retail

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

Press Release

- More than 30 suppliers fostered over 6 years as part of its shared growth efforts

▲Doosan Infracore has launched the 2020 Leading Supplier program placing top priority on the establishment of an MES essential in building a smart factory by its suppliers.

On July 30th of 2020, Doosan Infracore announced that it had launched the '2020 Leading Supplier' activities designed to help its suppliers build their own smart factories.

'Leading Supplier' is part of Doosan Infracore’s shared growth efforts aimed at enhancing its suppliers’ competitiveness through the dissemination of advanced cases in business operations and technical innovations. Based on its unique supplier development program, Doosan Infracore provides guidance in a range of areas such as production and operations, quality assurance, and manufacturing technology.

As the Leading Supplier in 2020, Doosan Infracore has chosen 6 suppliers such as Haesong Engineering which manufactures parts of the cooling system (radiators), Kunyoung Tech, Sung Won Hydraulics, Pyungsan Bolt Machine Industry, DY Solutec, and Myung-jin Company.

Doosan Infracore plans to help the suppliers set up the MES, one of the core smart factory programs, by the end of the year. The MES boosts production efficiency by integrating and managing real-time data about production plans, material flow, and quality information on a single platform. Doosan Infracore established a global MES at its Incheon plant in August of last year.

“We are extremely excited about being chosen as one of the recipients of Doosan Infracore’s transfer of smart factory know-how amid difficult market conditions due to COVID-19,” said Ryu Kyung-hwan, CEO of Haesong Engineering. “We will build an MES as early as possible as part of our efforts to be equipped for global competitiveness.

Doosan Infracore’s Procurement Division executive managing director Lee Yong-jin said, “Our global competitiveness should be strengthened by our suppliers’ advancement in smart technologies,” adding “We will spare no effort to help our suppliers build their own MES and grow into small but strong companies in digital technology.”

Doosan Infracore has been implementing the ‘Leading Supplier’ program since 2014 with the purpose of boosting its supplier competitiveness. Over the past six years, it has shared industry-wide advanced cases in business operations and technical innovations with more than 30 suppliers. For instance, World Tube, one of the 2019 program participants, has raised its welding quality of hydraulic pipes by more than 50% while Taehwa Co., Ltd. specializing in mechanical welding, has improved its delivery compliance rate by more than 28%.

▲Lee Yong-jin, Doosan Infracore’s Procurement Division executive managing director (right) and CEO Ryu Gyeong-hwan of Haesong Engineering Co., Ltd. signed an MOU for the 2020 Leading Supplier program.