Automated Manufacturing

Draft a manual and minimize human errors through production facility automation

Provides end-to-end intralogistics solutions for distributors and manufacturers by consulting, designing, engineering, and integrating automation systems.

고객도 놀라는 ‘셔틀 물류’, 두산로지스틱스 아시아 최대 높이 26미터 셔틀 랙 설치!

두산로지스틱스 물류자동화, 나이키도 선택했다

물류 자동화가 사업의 성패를 좌우한다!

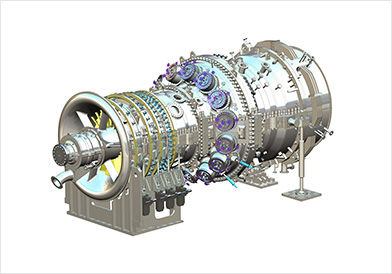

We lead the power industry by developing environmentally-friendly, high-efficiency gas turbines.

두산에너빌리티, 전투기 엔진 국산화 얼마나 앞당길까

두산중공업 가스터빈 시험 ‘순항’

A triple-energy production model that produces hydrogen, electricity, and heat at the same time using fuel cells.

수소, 전기, 열! 역대급 세 마리 토끼가 온다! 두산퓨얼셀 트라이젠 대활약!

혼자 세 몫 트라이젠, 팔방미인 수소드론 주목 받다!

The world's first fully electric, eco-friendly construction equipment that maximizes energy efficiency.

두산밥캣, CONEXPO에서 신제품 공개! 관람객들의 뜨거운 반응 현장 취재!

A collaborative robot solution that takes the lead in the 4th Industrial Revolution, providing differentiated cutting-edge technology and robot software (Dart-Suite) that can be easily used by anyone. Doosan collaborative robots have the highest precision and stability with torque sensors on all six axes—boasting of the highest precision and stability—and they can be applied to various processes.

두산로보틱스, 협동로봇 글로벌 리더를 꿈꾸다!

위기의 K-조선, 로봇으로 지켜낸다!

두산 SMR & 협동로봇, 글로벌 파트너십으로 세계 시장서 난다!

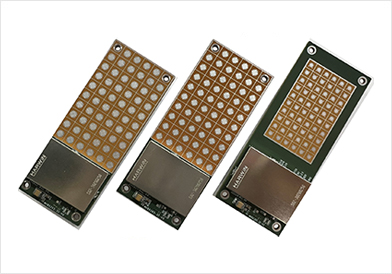

Plans to expand the business area to assembly, in addition to semiconductor testing, with various products and functions. Currently provides differentiated comprehensive solutions.

두산 반도체 사업, 앞으로가 더 기대되는 이유!

두산테스나 반도체 테스트 부문 글로벌 Top5 도약 준비 완료! 자율주행 자동차 Go? 우리는 Jump!

A core component of a 5G wireless repeater, which is an integrated solution module equipped with functions such as signal transmission and reception and frequency conversion.

??intro.technology_innovation.rnd.block2_4.video2_title_en??

5G의 진화, 6G로의 도약! 두산전자의 대활약!

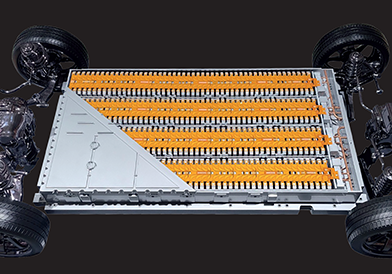

A material that replaces the wiring harness of the EV battery platform, which reduces the vehicle weight.

두산 PFC로 전기차가 가뿐해진다!

A core material in advanced electronics industries such as smartphones, semiconductors, and AI.

FCCL) 가장 핫한 신형 폴더블폰! 숨은 공로자는 바로 두산전자 FCCL

RCCL) Z플립에 들어가는 레시피라고? 두산 전자 연구소에 가 봤습니다!

두산전자, 구리가 첨단기술 속으로 #전자소재 #동박적층판 #CCL

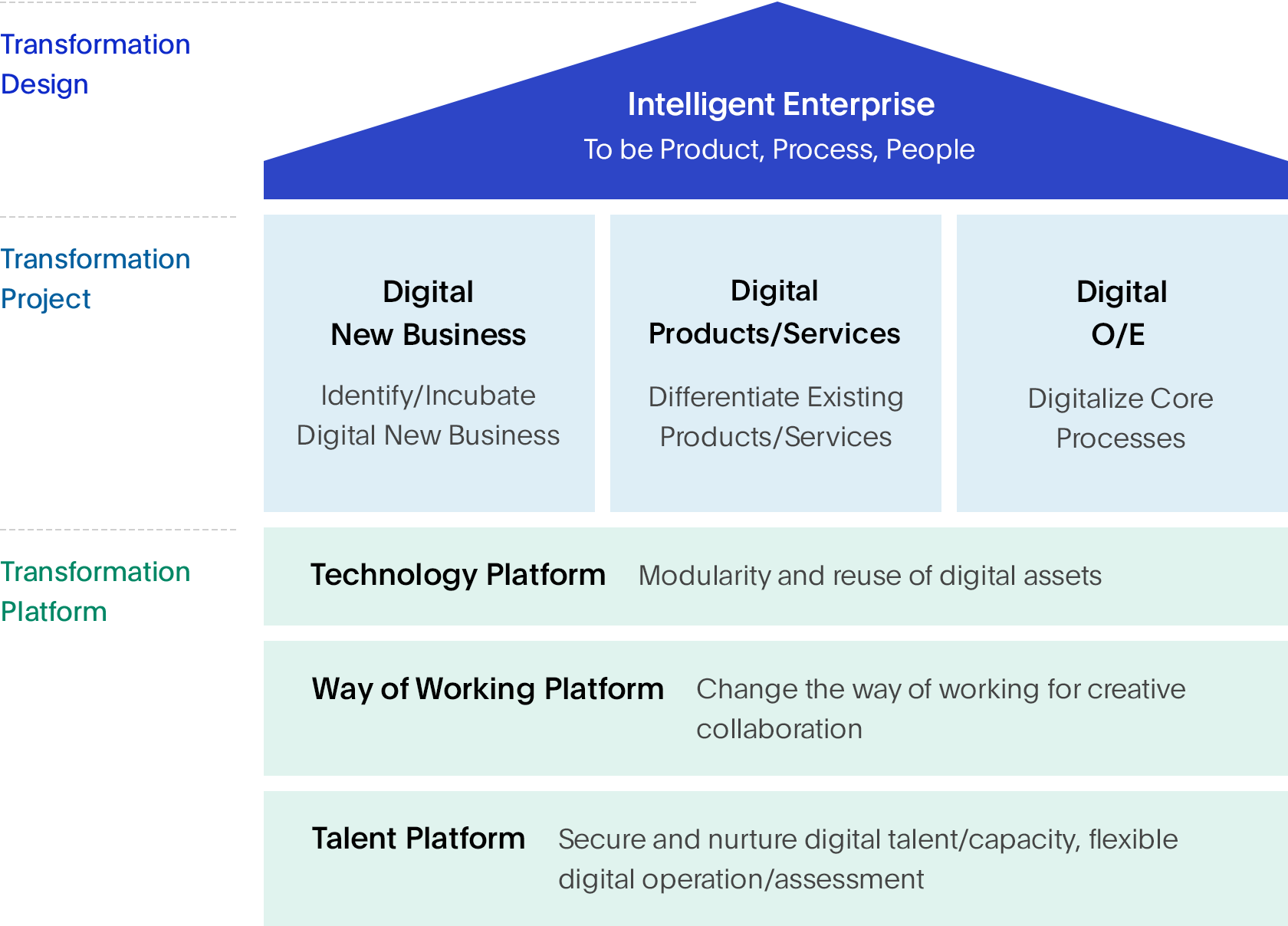

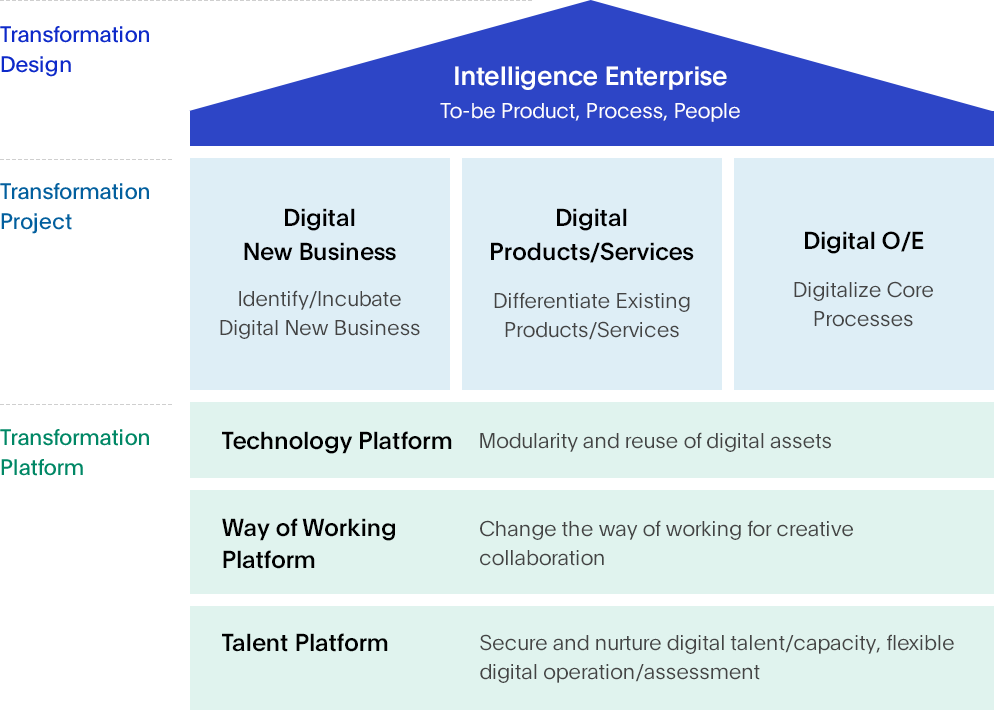

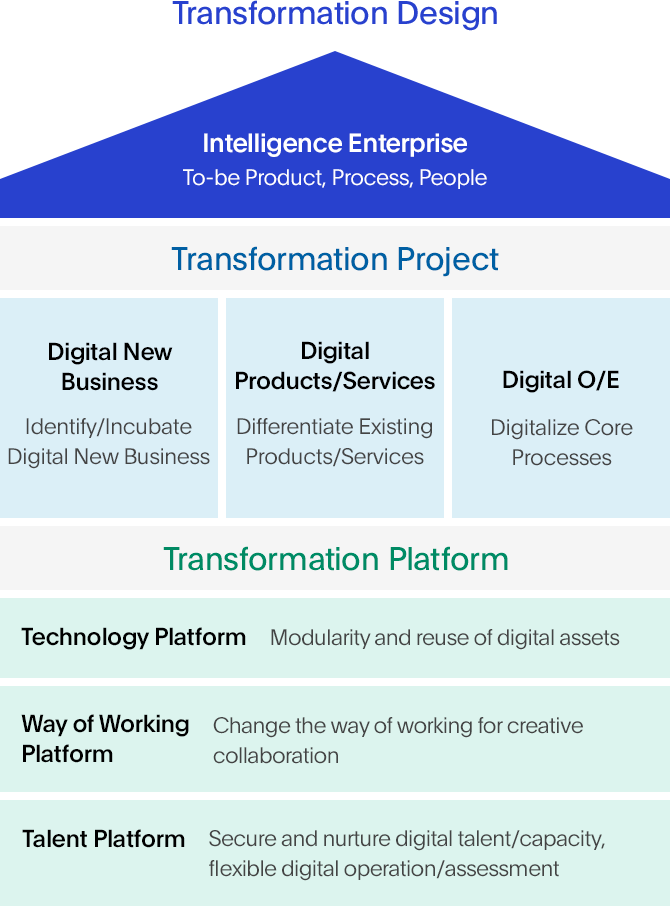

Doosan will gain a competitive edge in the aspects of agility (quick response to the market and customers), diversity (satisfying various customers) and empathy (suggesting solutions to the essential and potential problems of customers and the market) by designing To-Be products and processes, and hiring talented people. This is for the realization of Intelligent Enterprise, a direction of digital transformation and implementation of new digital businesses, digital products & services and digital O/E transformation projects using the digital transformation platform.

Identify digital new business opportunities and implement a business support process in a prompt mannerFoster the participatory idea generation and business incubation process

Doosan Enerbility : Digital Solutions

Dedicated to reducing pollutants from power plants and improving the competitiveness of the power generation business with self-developed digital solutions.

Develop new digital products and services for the existing products to create added valuePromote customer-oriented business management, and innovative data/UX-based services/business models

Doosan Fuel Cell : Cloud RMS

Cloud RMS (Remote Monitoring System) that remotely monitors eco-friendly fuel cell power plants 24/7 and responds to problems immediately 24/7

Redesign the processes and systems (to-be) for sales and operations planning (S&OP) and the digital factory to allow for an immediate response to the digital business (to-be)Increase agility by changing the way of working by using digital technology

Doosan Enerbility : Digital Factory

Using the IoT technology, we build a system that enables the sharing and monitoring of manufacturing information, and we build a “digital factory” by mounting sensors on manufacturing facilities to collect and analyze data with a goal of achieving manufacturing process optimization.

Automated Manufacturing

Draft a manual and minimize human errors through production facility automation

Digital Connectivity

Standardize/digitalize production and other relevant information, and connect data of different functions

Greater Visibility into Manufacturing

Gain greater visibility by digitalizing production information and automating data generation

Data-driven Optimization

Prevent quality failures and maximize productivity based on big data analysis